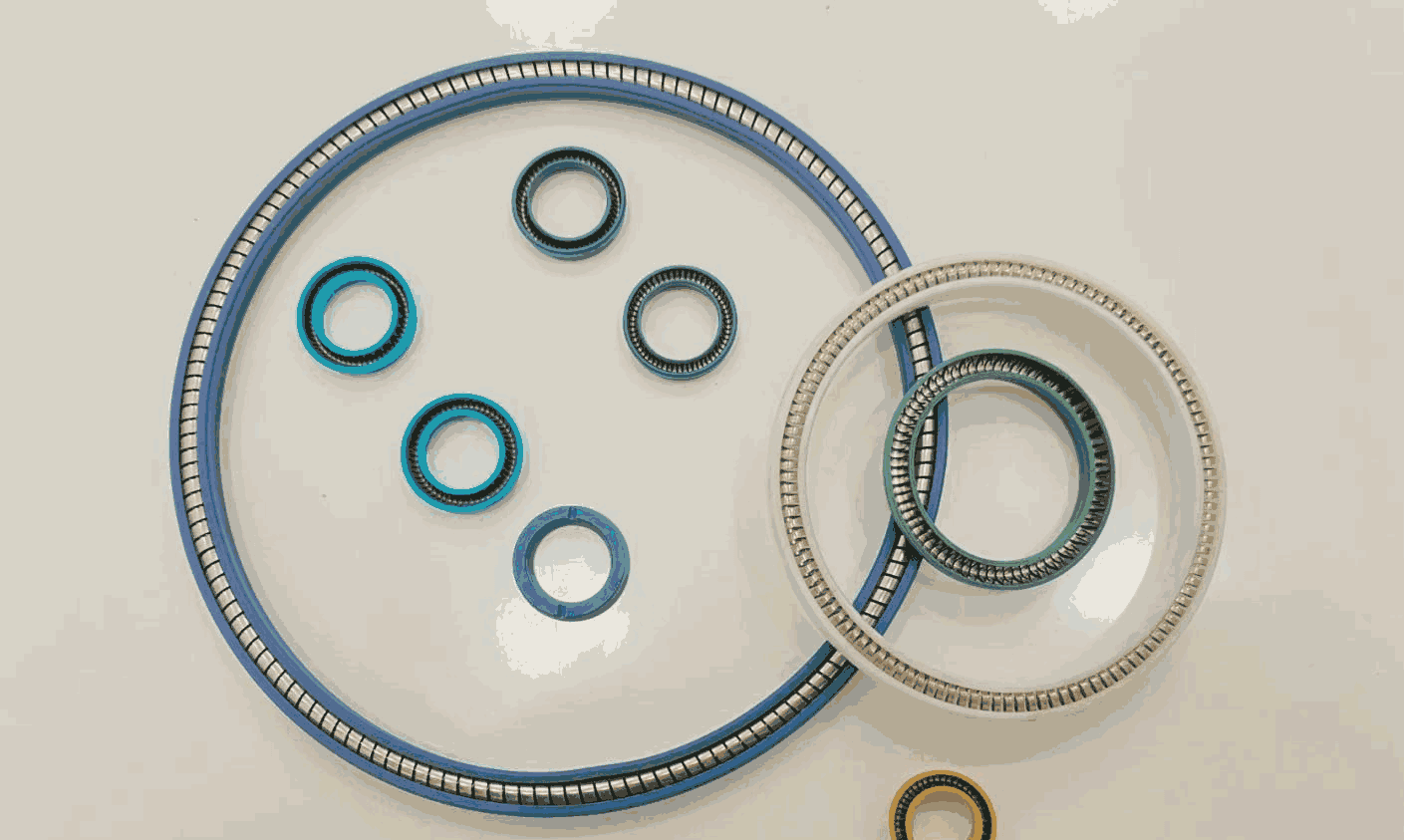

Spring Energized Seals

Spring-energized seals are engineered to deliver exceptional sealing performance in demanding environments where conventional seals such as O-rings, U-cups, and rubber lip seals often fail. These seals are ideal for applications that require superior chemical compatibility, pressure resistance, temperature stability, low friction, and high-speed capability.

What makes spring-energized seals unique is the combination of high-performance polymer jackets and precision-engineered metal springs. This design allows for a wide range of configurations, spring loads, and material options to meet your specific application requirements.

Handa Spring Energized Seals excel in scenarios where reliability and durability are critical. They provide a dependable sealing solution in industries such as aerospace, medical devices, oil & gas, semiconductor manufacturing, energy, and industrial automation. From the deep ocean to outer space, these seals ensure consistent performance, minimizing downtime and maximizing productivity.

CUSTOM MANUFACTURING

Custom Spring Energizers Seals

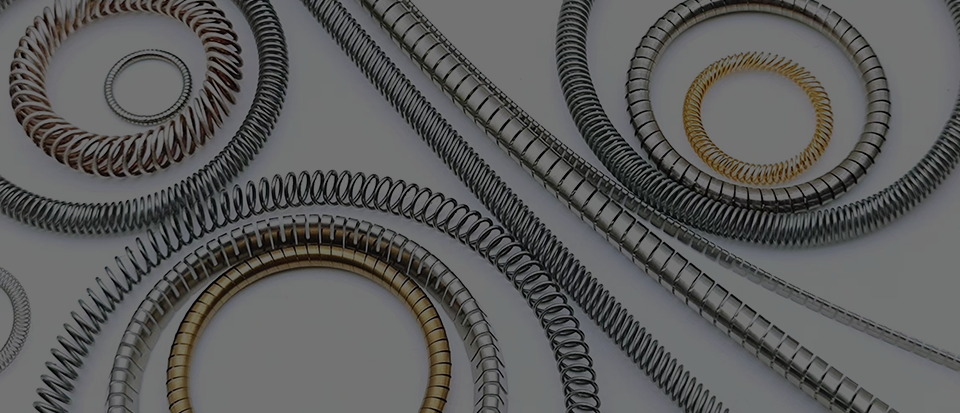

A core competitive advantage lies in our integrated manufacturing of spring-energized seals – including canted coils, V-springs, U-springs, and full-contact designs. We engineer material selection and spring configuration specific to sealing environments: acidic media, chlorine exposure, extreme pressure, and temperature cycles (-200°C to 800°C). This precision matching ensures superior seal longevity and leak-tight performance. Every application is unique. Handa provides full customization including:

- Custom geometries and profiles

- Spring force adjustment for optimal performance

- Material selection based on chemical, temperature, and pressure conditions

- Prototype development and quick turnaround

Request a quote to send us your specs or configure a part.

Spring Energizer Seals Manufacturing

At Hansealing, our sealing solutions are built upon a foundation of material excellence and proprietary manufacturing. These seals solve critical failure modes where traditional products (O-rings, U-cups, lip seals) degrade under:

-

Chemical incompatibility

-

Pressure extremes (to 10,000 PSI)

-

Temperature cycling (-200°C to +800°C)

-

High-speed dynamic stress

Spring Energizer Materials

Central to our capability is the in-house design and production of high-performance spring energizers using advanced alloys such as Elgiloy®, Hastelloy®, and other corrosion-resistant metals. This vertical integration ensures total control over performance, reliability, and quality. As material science evolves, we continuously integrate breakthrough chemistries and processing technologies into our product lines. Hansealing remains at the forefront of sealing innovation, combining next-generation materials with precision engineering to deliver superior value and performance in the most demanding applications.

To review more information about spring energizer materials, including options, features, and availability,click here.

Polymer Materials

Super comprehensive production ability from semi-finished shapes to finished parts, wide range of choice for polymer materials.

Spring Energizer Seals Configurations

Cantilever Spring Seal

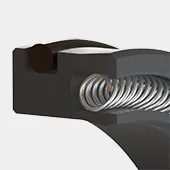

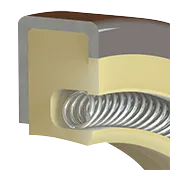

Hansealing Cantilever Spring Seals utilize a V-shaped spring encased in a high-performance polymer jacket. During installation, the V-spring is compressed, generating consistent sealing energy that ensures a positive and reliable seal. Featuring a linear load curve and an exceptional deflection range, Hansealing Cantilever Spring Seals offer outstanding versatility. They are commonly used as high-performance replacements for rubber U-cups that have failed due to chemical corrosion, extreme temperatures, excessive friction, or wear.

These seals are ideally suited for reciprocating applications such as shock absorbers, hydraulic cylinders, pumps, and compressors. The unique spring design focuses sealing force at the front lip, making it highly effective as an environmental excluder or for scraping viscous media. Additionally, the spring cavity can be filled with FDA-compliant silicone for clean-in-place (CIP) applications in regulated industries.

Canted Coil Spring Seal

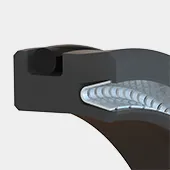

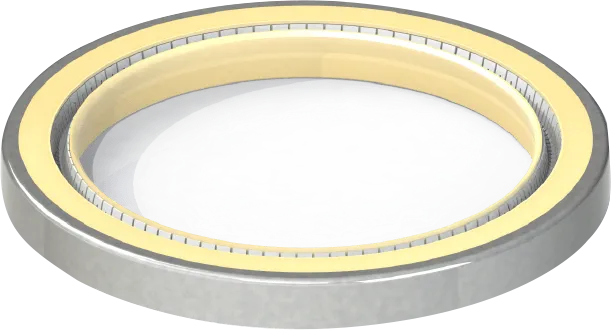

Hansealing Canted Coil Spring Seals feature a precisely wound wire spring enclosed within a high-performance polymer jacket. Unlike conventional spring designs, the canted coil provides a semi-linear load curve, delivering stable sealing force across a wide deflection range. This makes them ideal for friction-sensitive applications such as HPLC systems, encoders, and flap actuators, where consistent performance is essential. In battery-powered devices, these seals help minimize friction and extend battery life.

Hansealing Canted Coil Spring Seals feature a precisely wound wire spring enclosed within a high-performance polymer jacket. Unlike conventional spring designs, the canted coil provides a semi-linear load curve, delivering stable sealing force across a wide deflection range. This makes them ideal for friction-sensitive applications such as HPLC systems, encoders, and flap actuators, where consistent performance is essential. In battery-powered devices, these seals help minimize friction and extend battery life.

Helical Spring Seal

Hansealing Helical Spring Seals use a wound ribbon metal spring enclosed in a durable polymer jacket. The helical spring design delivers a high load over a limited deflection range, making it an excellent choice for applications that demand very tight sealing. Best suited for static or slow dynamic conditions, these seals are commonly applied in stem seals and cryogenic valves, where additional sealing force is needed to withstand extreme thermal effects.

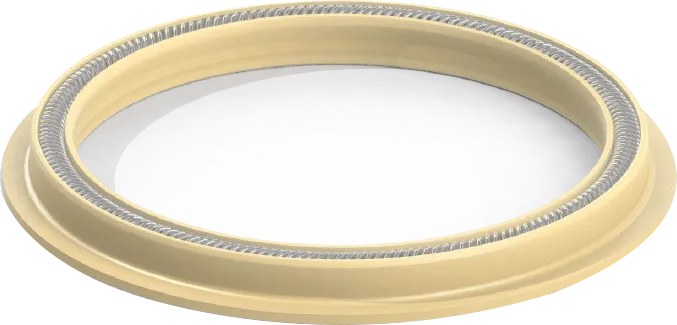

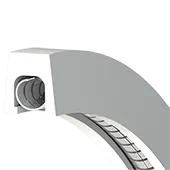

Flanged Seal

Hansealing Flanged Seals are a specialized type of radial seal designed with an extended flange to resist rotary forces and ensure reliable retention. The flange, formed as an extension of the heel, fits into a housing counterbore where it is compressed during assembly. This creates a positive mechanical lock that keeps the seal stationary, enhancing both durability and sealing performance.

Flanged seals are well-suited for equipment incorporating end plates, as installation is simple and robust. They also provide an added level of redundant sealing on the static side of the gland. Typical applications include process machinery such as mixers, augers, and spool valves—where product containment and long-term reliability are essential.

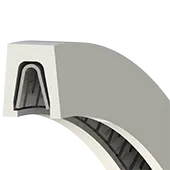

O-Ring Heel Seal

Hansealing O-Ring Heel Seals are an effective choice for rotary service applications where additional gland length is available. By integrating an O-Ring at the heel of the radial seal, a high-friction interface is created at the bore, helping resist rotary forces while providing anti-rotation stability. With proper hardware design, these seals deliver a high level of performance, making them particularly suitable for sealing gaseous or low-viscosity fluids where redundant sealing and reliability are essential.

O-Ring OD Seal

Hansealing O-Ring OD Seals are designed for rotary service applications where additional gland diameter is available. By adding an O-Ring on the outside diameter of a radial seal, a high-friction interface is created at the bore to resist rotary forces and improve sealing reliability. Since the O-Ring is softer than the jacket material, it provides greater compliance and ensures a tight seal on the bore. This design is commonly applied in vapor recovery systems and vacuum pumps, where low running friction and high sealing efficiency are critical.

Cased Spring Seal

Hansealing Cased Spring Seals are engineered for extreme rotary service, offering both durability and reliable sealing. In this design, a metal case surrounds the spring seal and is press-fit into the hardware bore. The metal-to-metal fit provides a secure seal and a highly effective anti-rotation mechanism.

These seals are ideal for rotary applications such as gearboxes and power transmission systems, where performance and reliability are critical. They are also well-suited as rod end scrapers, effectively excluding aggressive media in demanding environments.

Internal Face Spring Seals

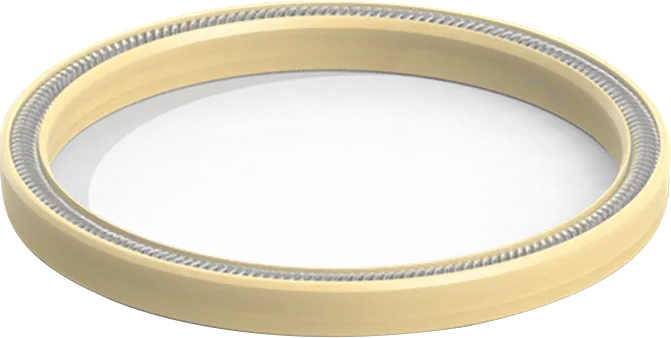

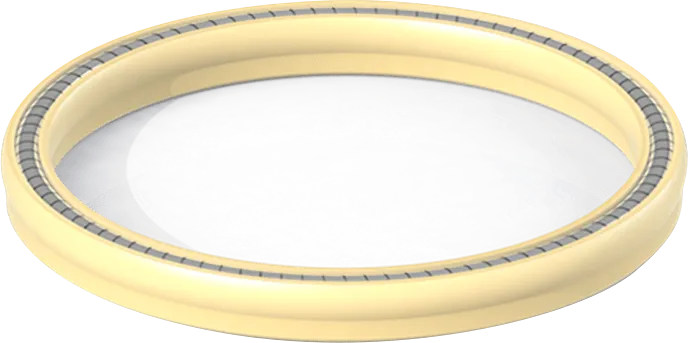

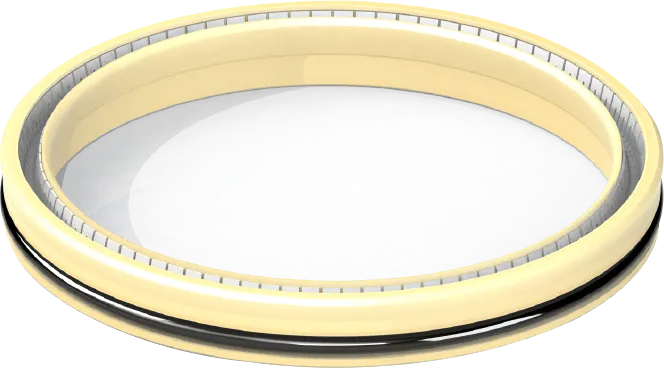

Internal Face Spring Seals are primarily used in static sealing applications. They are designed to retain pressure within vessels, making them effective for lid closures and pipe flange connections. Compared with O-Rings, PTFE-based Face Spring Seals deliver enhanced pressure capacity, chemical resistance, and temperature range. They are also well-suited for cryogenic applications, where reliable sealing is essential.

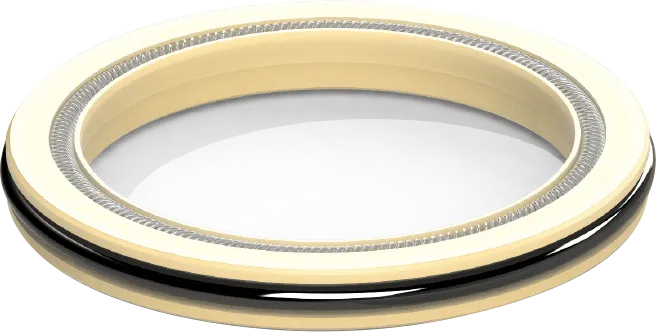

External Face Spring Seals

External Face Spring Seals are commonly applied in static sealing environments where the goal is to exclude environmental media from exposed joints, hinge points, or pipe fittings. Compared with O-Rings, PTFE-based Face Spring Seals offer superior chemical compatibility, pressure handling, and temperature performance. They are also effective in cryogenic conditions, providing reliable protection in demanding applications.

Why Choose Hansealing?

We’re a trusted seals manufacturer for both stock and custom seals.

- In-house manufacturing – no middleman, direct factory support

- Expert engineering for critical sealing applications

- Ability to handle small batches and large-scale production

- Fast delivery and responsive customer service

Top Industry Applications: Oil & Gas and Medical

Oil & Gas

Spring energizers are one of the most common components used to provide a leak-proof seal in oil and gas applications that involve extreme, dynamic environment. When paired with a durable polymer jacket, spring energizers provide leak-protection tight seal even in dynamic conditions, such as rotational or reciprocating motion. The spring ensures continuous contact between the seal and the mating surface, compensating for wear, pressure fluctuations, and misalignments.

When crafted from quality materials, spring energizers also offer exceptional resistance to high pressures, extreme temperatures, and corrosive chemicals. By preventing leaks and performing well in extreme environments, spring energized seals enhance the safety, efficiency, and longevity of critical oil and gas equipment.

Common oil & gas uses for spring energizers:

- Valves

- Pumps

- Compressors

- Downhole tools

Medical

Spring energizers provide precise, repeatable force and reliable connections in critical medical applications. Their loads and deflection are customizable, making them ideal for use in quick connect/disconnect uses for surgical instruments and diagnostic equipment, as well as and in electrical enclosures or used with data transmission cables where they are customized to meet impedance specifications to protect equipment from crosstalk interference. In EMI/RFI shielding applications, spring energizers provide an economical design that can reduce radiated and conducted interference to prevent premature failure in electrical devices.

In addition to the above, spring energizers are frequently used as leak-proof seals in infusion pumps, ventilators, and more. In seal applications, spring energizers are are paired with a polymer jacket, often made from biocompatible materials like PTFE or UHMWPE, to guard against leaks under changing conditions such as repeated movements or pressure fluctuations.

Common medical uses for spring energizers:

- Quick connect/disconnect applications

- Leak-proof seals

- Electrical connectors

Questions about our Spring Energizers Seals?

Contact us. Our staff includes sales professionals who can help with pricing along with design engineers and manufacturing experts who can answer even the most difficult technical questions. Get in touch for questions about seal or any of our other products, and we’ll make sure you’re connected with the person most qualified to help.