All Products> Spring Energized Seals

Helical Spring Seal

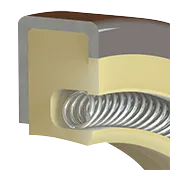

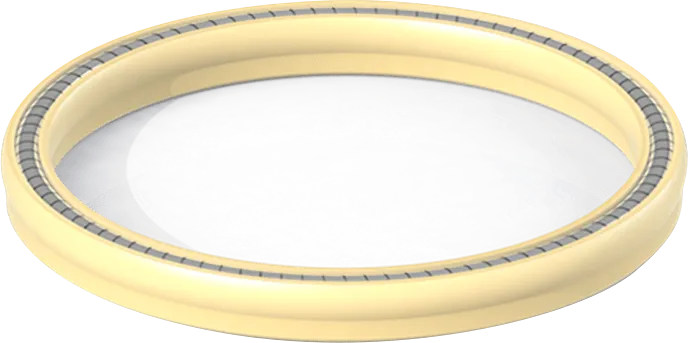

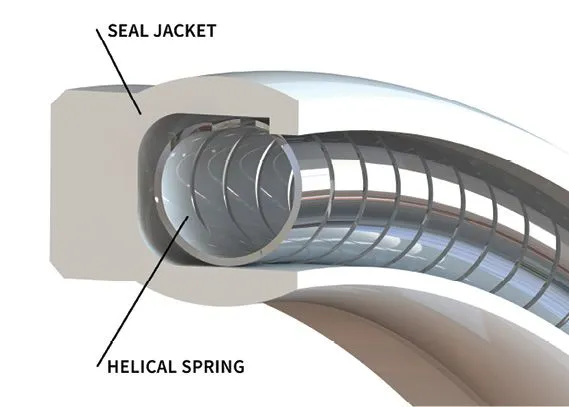

Hansealing Helical Spring Seals are advanced spring-energized seals, designed for exceptional sealing performance across a range of applications. Featuring a helical spring—a coiled ribbon of thin metal—encased in a durable polymer jacket, these seals apply constant pressure to the sealing surface, ensuring a tight, reliable seal even under fluctuating pressure and temperature conditions.

The high load versus deflection range of the helical spring makes it ideal for static or slow dynamic applications, such as stem seals and cryogenic valves, where additional sealing force is needed to overcome thermal effects and maintain performance. The consistent load helps adapt to surface irregularities, ensuring optimal sealing and preventing leakage.

These seals are especially effective in cryogenic environments, where they withstand extremely low temperatures while maintaining a strong seal. They are also ideal for stem seals, offering a secure and reliable fit.

Made from high-performance materials like PTFE (Teflon), UHMWPE, and PEEK, Hansealing Helical Spring Seals are highly durable and resistant to chemical attack. PTFE provides low friction and excellent chemical resistance, UHMWPE offers wear resistance, and PEEK delivers superior strength for high-pressure and high-temperature environments.

With their versatility and robustness, Hansealing Helical Spring Seals are crucial for modern industrial applications, including cryogenic systems, high-pressure environments, and slow reciprocating systems, ensuring long-lasting and reliable performance.

MANUFACTURED SPRINGS

Custom Seals And Springs Energized

Hansealing Helical Spring Seals deliver precision sealing for piston applications with complete customization options. The spring element can be tailored in terms of design, load force, and material to match operating conditions—whether requiring high sealing force, low friction, or resistance to extreme temperatures.

The jacket material is also customizable, with options such as PTFE, UHMWPE, and PEEK, ensuring compatibility with aggressive chemicals, cryogenic conditions, or high-pressure systems. This flexibility enables Hansealing to provide sealing solutions that perfectly fit each customer’s unique application.

Typical Range of Application

Values and ratings in this catalog are based on industry standard applications operating under ideal conditions. The customer should assume responsiblity for validation testing of performance and suitabilty of Eclipse Engineering products. Hansealing Engineering accepts no liabilty for the accuracy and applicabilty of provided information.

*Ratings will vary based on materials and operating conditions

| Types | SEAL ID(mm) | Pressure(Mpa) | Temperature(℃) | Linear velocity(m/s) |

|---|---|---|---|---|

| Reciprocating seal | 3~2200 | ≤20 | -200~320 | ≤15 |

| Rotary seal | 3~2200 | ≤20 | -200~320 | ≤3 |

Dimensional Data

The chart below shows the standard dimensions for our Standard Cantilever V-Spring. All dimensions are subject to standard manufacturing tolerances. Those tolerances may be requested if needed. Each Cantilever V-Spring is manufactured in its own standard tool & die set. If these dimensions do not work for your situation, minor variations to the “L“ and “K” dimensions can be made with minor adjustments to our tooling. However, if you are in need of a more aggressive change (such as the width of the raw material or radius dimensions) we suggest you inquire about one of our 100 or more nonstandard cross-sections of spring.

*If you still can’t find the geometry you like, a unique toolset can be designed specifically for your application. Ask an MW expert for details.

Installation Dimensions(mm)

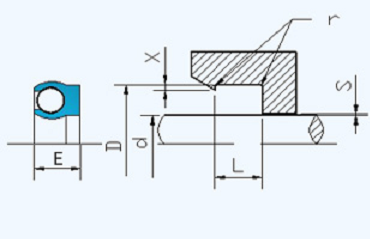

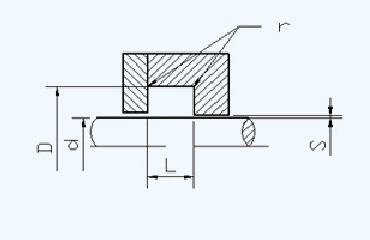

Installation Dimensions Drawing

| Ød(h9) | ØD(H9) | L=E+0.1 | r | X | Maximum radial clearance(Smax) | |||

| 2Mpa | 10Mpa | 15Mpa | 20Mpa | |||||

| 3.0~9.9 | d+2.6 | 2.3 | 0.15 | 0.4 | 0.08 | 0.05 | 0.03 | 0.02 |

| 10.0~19.9 | d+3.6 | 2.9 | 0.2 | 0.4 | 0.08 | 0.05 | 0.03 | 0.02 |

| 20.0~29.9 | d+4.6 | 3.3 | 0.25 | 0.4 | 0.01 | 0.07 | 0.05 | 0.03 |

| 30.0~39.9 | d+5.6 | 4.1 | 0.3 | 0.7 | 0.01 | 0.07 | 0.05 | 0.03 |

| 40.0~49.9 | d+6.6 | 4.9 | 0.35 | 0.7 | 0.12 | 0.08 | 0.06 | 0.05 |

| 50.0~59.9 | d+7.6 | 5.7 | 0.4 | 0.8 | 0.12 | 0.08 | 0.06 | 0.05 |

| 60.0~69.9 | d+8.6 | 6.5 | 0.45 | 0.8 | 0.15 | 0.09 | 0.08 | 0.06 |

| 70.0~79.9 | d+9.6 | 7.3 | 0.5 | 0.9 | 0.15 | 0.09 | 0.08 | 0.06 |

| 80.0~89.9 | d+10.6 | 8.6 | 0.55 | 0.9 | 0.2 | 0.1 | 0.09 | 0.07 |

| 90.0~109.9 | d+11.6 | 9.1 | 0.6 | 0.9 | 0.2 | 0.1 | 0.09 | 0.07 |

| 110.0~129.9 | d+12.6 | 9.7 | 0.65 | 1.0 | 0.25 | 0.12 | 0.1 | 0.08 |

| 130.0~149.9 | d+13.6 | 10.5 | 0.7 | 1.0 | 0.25 | 0.12 | 0.1 | 0.08 |

| 150.0~169.9 | d+14.6 | 11.3 | 0.75 | 1.0 | 0.3 | 0.14 | 0.12 | 0.1 |

| 170.0~189.9 | d+15.6 | 12.1 | 0.8 | 1.0 | 0.3 | 0.14 | 0.12 | 0.1 |

| 190.0~209.9 | d+16.6 | 12.9 | 0.85 | 1.0 | 0.35 | 0.15 | 0.14 | 0.12 |

| 210.0~249.9 | d+17.6 | 13.7 | 0.9 | 1.0 | 0.35 | 0.15 | 0.14 | 0.12 |

| 250.0~299.9 | d+18.6 | 14.5 | 0.95 | 1.0 | 0.4 | 0.18 | 0.15 | 0.14 |

| 300.0~2200 | d+19.6 | 15.3 | 1.00 | 1.0 | 0.4 | 0.18 | 0.15 | 0.14 |

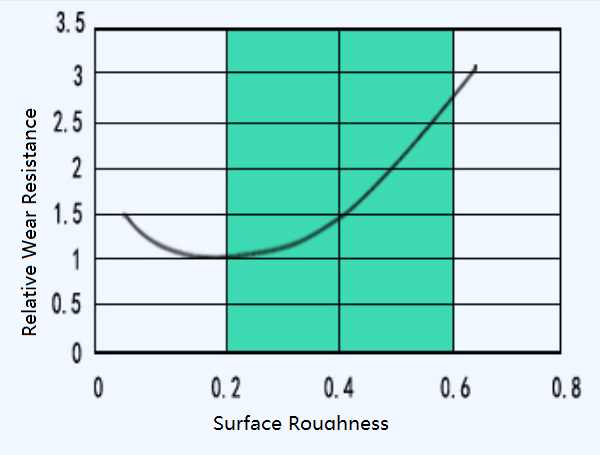

Recommended Surface Roughness for Mating Parts

Dynamic Surface Roughness Chart

| Sealing Medium | Surface Roughness | |

|---|---|---|

| Dynamic Surface | Static Surface | |

| Cryogenic | 0.1 to 0.2 Ra | 0.1 to 0.2 Ra |

| Helium | 0.15 to 0.3 Ra | |

| Hydrogen | ||

| Freon | ||

| Air | 0.15 to 0.3 Ra | 0.3 to 0.8 Ra |

| Nitrogen | ||

| Argon | ||

| Natural Gas | ||

| Fuel | ||

| Water | 0.2 to 0.4 Ra | 0.2 to 0.4 Ra |

| Hydraulic Oil | ||

| Crude Oil | ||

| Sealant | ||

Ordering Example

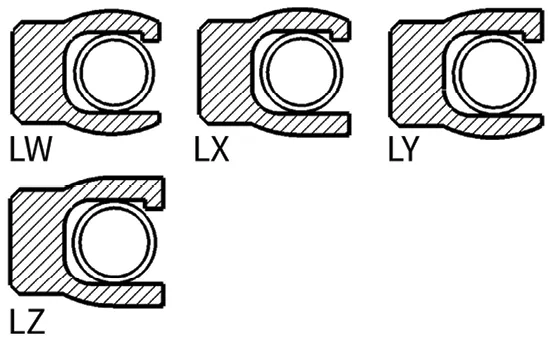

Lip Style

| Example P/N: HHS-P-234-LW-ET000-H-P | |

|

HHS

|

= Seal Series (Helical Spring) |

|

P

|

= Piston/ROD |

|

234

|

= Seal Inner Dimensions |

|

LW

|

= Lip Style |

|

ET000

|

= Seal Material Code |

|

H

|

= Spring Load: Light = L, Medium = M, High = H |

|

P

|

= Spring Material P – 17-7 PH Stainless Steel E – Elgiloy® , Click here see more |

Cavity Tool Drawings

Download V Spring Cavity Tool Drawings

Have Questions?

Talk with our experts today and let us help you figure out the best solution.